Magnetic

surveying is a geophysical method used in the mining industry to locate,

calculate and determine quantities of minerals beneath the ground. It monitors

spatial variations in the Earth's magnetic field, which allows specialists to

detect and map artifacts, features and various other formations beneath the

Earth's crust. These formations are often large deposits of minerals such as

iron, steel, brick and other form of rock that are highly magnetic.

The tools used

in magnetic surveying are called magnetometers. These scientific instruments

are tuned to measure both the strength of the magnetic field as well as the

direction. Currently, there are three different types of magnetometers used by

the mining industry to be able to detect these anomalies, and they include:

-

Gradiometers, which are pairs of meters

separated at a fixed distance horizontally. The two values are then subtracted

which provides an accurate measurement of the fields of gravity caused by

anomalies.

-

Fluxgate Magnetometers, typically consist of a

‘sense' coil and a ‘drive' coil that is wound around a core. An alternating

current is applied to the drive coil which causes both plus and minus

saturation. As there is an opposite polarity, when a magnetic field anomaly is

applied, it will aid one polarity and oppose the other.

-

Caesium Vapour Magnetometers, which consists of

a photon emitter which contains a caesium lamp, an absorption chamber

containing the vapour and a ‘buffer' gas, and also a photon detector.

Complicated sounding, however in practice it's very simple, as a magnetic field

comes into contact with this magnetometer, the polarization of the field will

cause the caesium atoms to pass through and be measured by the photon detector.

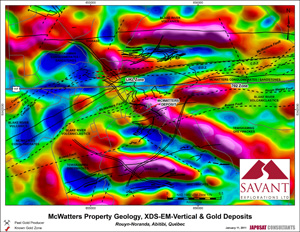

Aeromagnetic

surveying is another form of magnetometer. Rather than being placed on the

ground, the magnetometer is onboard or is toed behind an aircraft. This allows

much larger areas to be explored in less time. Aeromagnetic surveying is also

typically more accurate because the plane moves at a uniform speed. The process

of doing aeromagnetic surveying is similar to the small magnetometers listed

above, but allows much larger areas of the earth's surface to be covered. In

airborne magnetic surveys, the aircraft will typically fly in grid patterns as

the magnetometer picks up slight differences in the magnetic field that are

then expressed on maps as coloured imagery. This method of surveying is

preferential in the mining industry because it provides a vast area of surveyed

land in less time than traditional ground based surveying would take. Once the

aeromagnetic survey is complete and the overall picture can be analyzed, in

some cases a ground based survey is a logical step to target specific areas of

interest.

The practice

of airborne magnetic surveying is important to companies seeking magnetically

active resources while ground based magnetic surveys are useful if the area is

small or a specific area is the ideal target. Both play a role in the mining

industry and act as an important tool to companies seeking the minerals

entombed under the Earth's surface.